Asme Flange Bolt Torque Chart

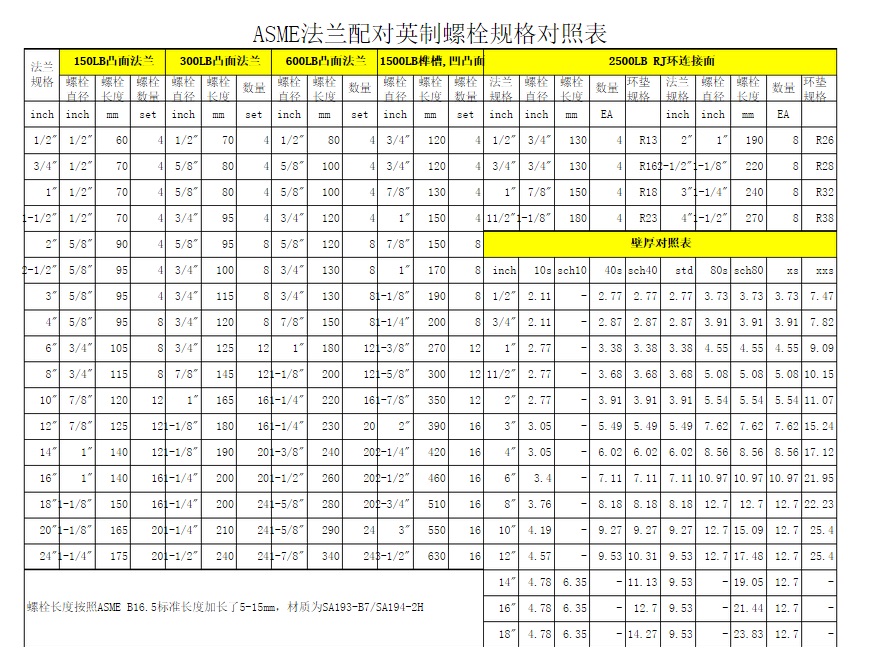

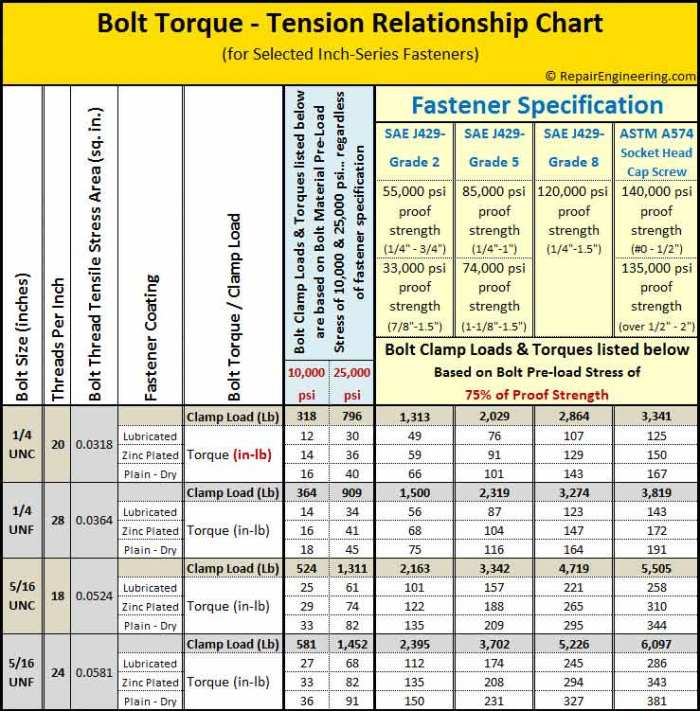

Asme Flange Bolt Torque Chart - Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under normal assembly conditions. Web bolt torque values for asme b16.5 series a class 150# flat flanges with a193 grade b7 bolts. For full face homogenous elastomeric gaskets For full face homogenous elastomeric gaskets. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Apply lubricant to bolt threads and faces of nuts. Web i'm looking for the recommend torque to put on an asme flange. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. Tables for spiral wound gaskets (asme b16.5) and for insulating gaskets. Tables for spiral wound gaskets (asme b16.5) and for insulating gaskets. The application of the recommended torque is only valid for the listed teadit products. I can't seem to find it in asme b16.5. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Apply lubricant to bolt threads and faces of nuts. The torque values are approved for spiral wound graphite and ptfe filled gaskets. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. Clean the bolts and lubricate them with a quality lubricant, such as an oil and graphite mixture. Web i'm looking for the recommend torque to put on an asme flange. Web pipe flange bolt torque chart. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: The torque values are approved for spiral wound graphite and ptfe filled gaskets. Web look up flange bolt sizes and torque patterns. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according to the national boiler code, installed in accordance with the central plastics company flange installations guidelines. Web pipe. Spiral wound and ring joint. Web these bolt torque values are intended for use as guidelines only and are based on ideal conditions, perfect flanges, flange alignment & new well lubricated bolts/nuts according to the national boiler code, installed in accordance with the central plastics company flange installations guidelines. Web flange materials:astm a105, astm a182 grades f50 and f51, astm. In this article, you will learn about the torque sequence of pipe flanges. Spiral wound and ring joint. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Place the gasket on the flange surface to be sealed. I can't seem to find it in asme b16.5. Place the gasket on the flange surface to be sealed. Tables for spiral wound gaskets (asme b16.5) and for insulating gaskets. Web ses 75% of the yield strength. Place the bolts into the bolt holes. These torque values are intended for use as quidelines only & are based on perfect conditions. Web flange torque charts listed by nps and by flange class. The entire bolt pattern shall be tightened at least three times around the flange at. Web flange materials:astm a105, astm a182 grades f50 and f51, astm a350 grades lf2 and lf3, astm a694 grades f52 and f60. For full face homogenous elastomeric gaskets. Web these bolt torque values are. Apply lubricant to bolt threads and faces of nuts. These are 304 ss material. Place the bolts into the bolt holes. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16. The entire bolt pattern shall be tightened at least three times around the flange at. Flanges according to asme b16.5 norm. In this article, you will learn about the torque sequence of pipe flanges. The above table is applicable only for astm a320 grade b8, class 2 and a193 grade b8, class 2 stud bolts. Clean the bolts and lubricate them with a quality lubricant, such as an oil and graphite mixture. Web look up. Web bolt torque values for asme b16.5 series a class 150# flat flanges with a193 grade b7 bolts. Service temperature range:minus 101 thru’ plus 400oc (per piping class). Web i'm looking for the recommend torque to put on an asme flange. This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. Place the bolts into the bolt holes. Spiral wound and ring joint. For full face homogenous elastomeric gaskets. Web flange torque charts listed by nps and by flange class. The above table is applicable only for astm a193 grade b7 and a193 grade b16 stud bolts. Just enter the flange size, type, and class, and the tool instantly shows the asme values for: Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web bolt torque values for asme b16.5 series a class 150# flat flanges with a193 grade b7 bolts. Web bolt torque values for asme b16.47 series a class 150# flat flanges with a193 grade b7 bolts. For full face homogenous elastomeric gaskets Web welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under normal assembly conditions. The torque chart is for reference only and assumes properly lubricated astm a193 b7 stud bolts with astm a194 2h steel nuts. The length of the stud bolt does not include the height of the points. In this article, you will learn about the torque sequence of pipe flanges. For full face homogenous elastomeric gaskets. Place the gasket on the flange surface to be sealed. The pressure rating of the material may vary depending on the grade. Place the bolts into the bolt holes. Apply lubricant to bolt threads and faces of nuts. Even though flange blot toque calculation is possible, they are normally selected from the pipe flange bolt torque chart. Bolting materials:astm a193 grades b7 and b7m, astm a320 grades l7, l7m and l43. The above table is applicable only for astm a320 grade b8, class 2 and a193 grade b8, class 2 stud bolts.ASME Flange B16.5 Chart 300 LB Mechanical Engineering Nature

Asme Bolt Torque Chart

ASME Bolting Assembly Torque Values [PDF Document]

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word

Asme Bolt Torque Chart

ASME Bolting Assembly Torque Values

Bolt Dimension For ASME B16.5 flange

Asme Bolt Torque Chart

Bolt Torque Table Asme Elcho Table

ASME Flange Chart

Web By The Bolts Is Difficult To Measure Directly, Torque Is Used As A Convenient Way To Approximate The Desired Load.

Web Flange Torque Charts Listed By Nps And By Flange Class.

Web I'm Looking For The Recommend Torque To Put On An Asme Flange.

The Entire Bolt Pattern Shall Be Tightened At Least Three Times Around The Flange At.

Related Post:

![ASME Bolting Assembly Torque Values [PDF Document]](https://cdn.vdocuments.net/doc/1200x630/577c7c141a28abe0549934de/asme-bolting-assembly-torque-values.jpg?t=1661730594)