Pulley Size Chart

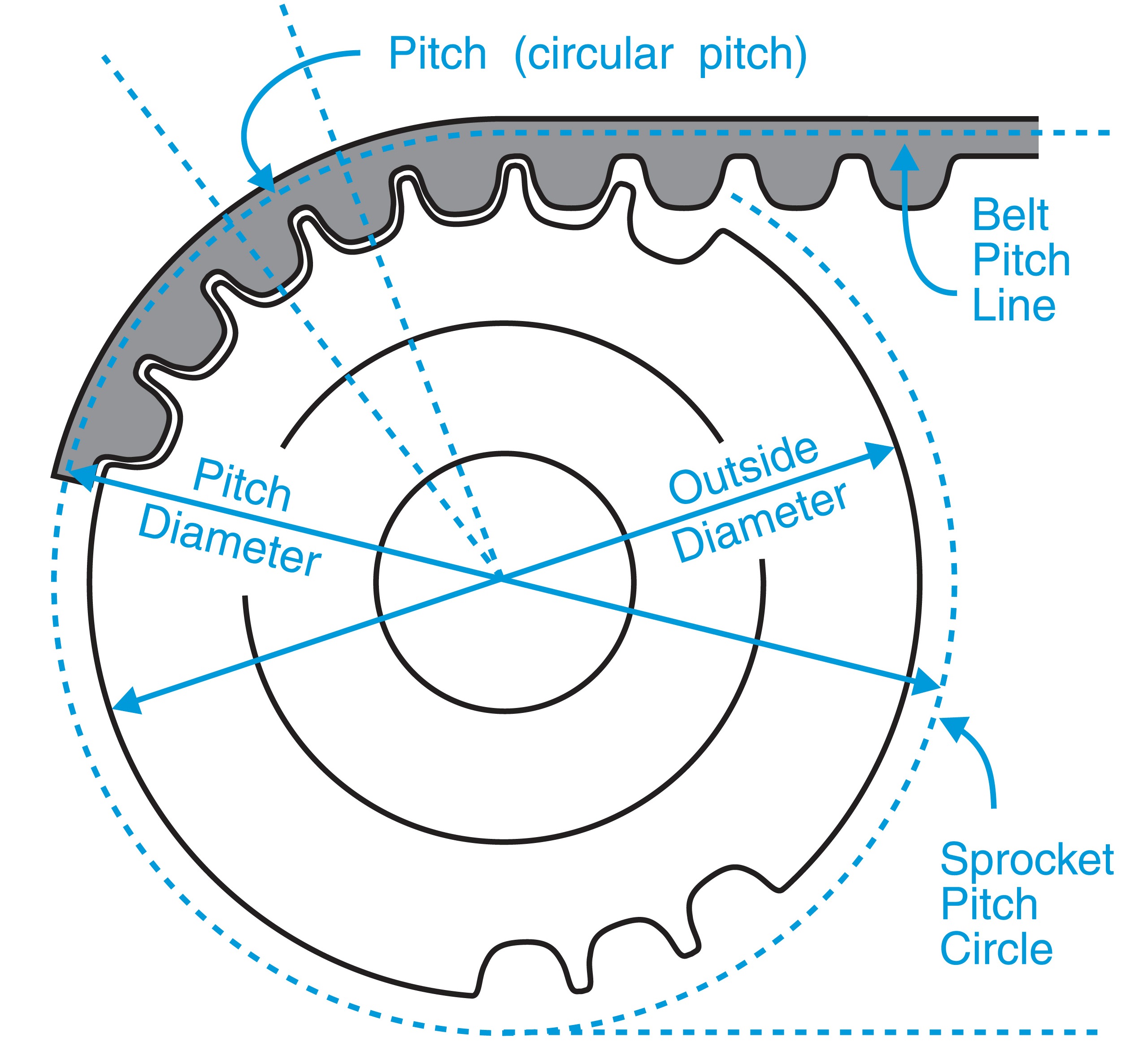

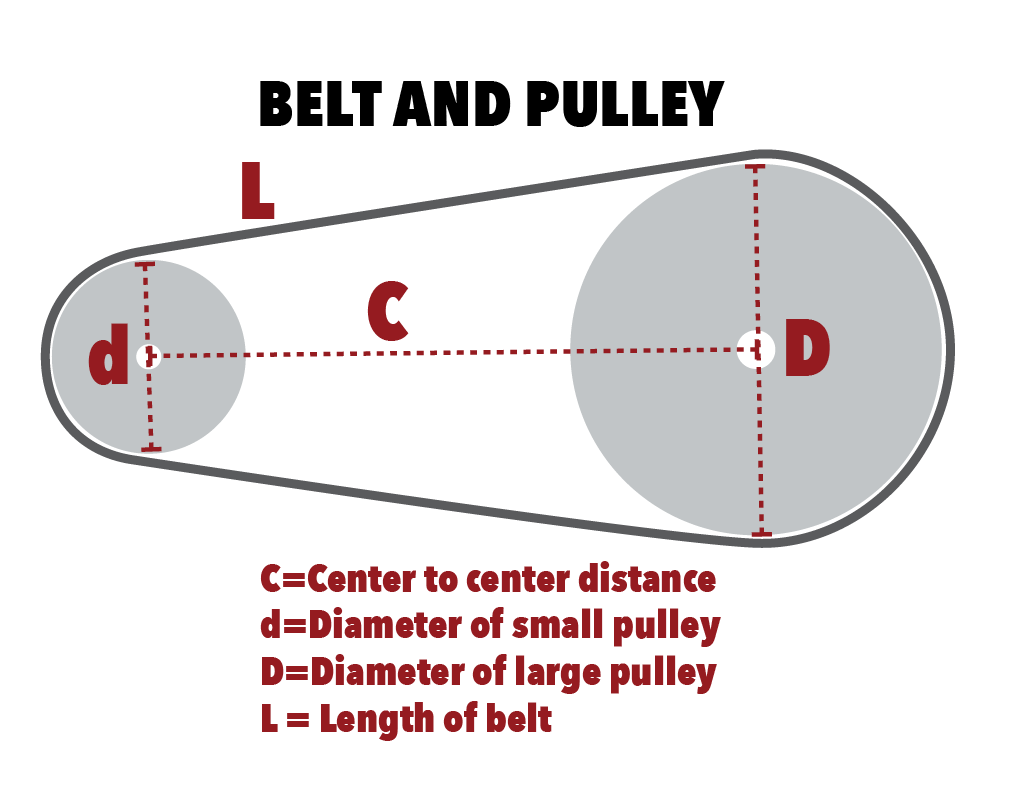

Pulley Size Chart - Web learn how to measure your pulley or sheave. Terre products measuring guide explains pulley specs and dimensions. To find the rpm (n₂) of the driven pulley, measure its diameter (d₂) and apply the values alongside the driving pulley’s rpm (n₁) in the formula. Obtain the motor’s rpm specification to understand the input speed. V and flat belt design and engineering data. Web determine which pulley acts as the driver (higher rpm) and which is driven (lower rpm). Web shiftbulk is a collaborative platform that simplifies the design and purchasing process for belt conveyor systems. 5/5 (1,408 reviews) Quickly determine the size of any belt. Consider belt type and width: Web below that, there some numbers are given for factory equipped shovelheads. Motor and equipment speed for pulleys with different diameters are indicated in the charts below: Obtain the motor’s rpm specification to understand the input speed. Calculate the required speed ratio between the motor and driven equipment based on the application’s needs. In order to replace or install the proper belt for your pulleys, you need to have an accurate measurement of the length so you can choose the right one. Are finished in a black coating; Each manufacturer will have different recommendations based on your project’s specifications, taking into account shaft speeds, power transmission, environment, and other concerns. All belts and pulleys can be found in the webshop. Click on the images below to enlarge. For a pulley system like this, the product of pulley diameter d and rpm n is the same for both driver and driven pulley. Outside diameter, or the distance across the pulley when measured between groove edges. Belt profile, or the style and sizes of the belt being integrated. Terre products measuring guide explains pulley specs and dimensions. Quickly determine the size of any belt. Web what is the right size belt and pulley for your motorcycle? Web learn how to measure your pulley or sheave. All belts and pulleys can be found in the webshop. D₁ × n₁ = d₂ × n₂. Belt profile, or the style and sizes of the belt being integrated. Web determine which pulley acts as the driver (higher rpm) and which is driven (lower rpm). 8c 8 9 1 % 0 % % b 4 & belt series pitch diameter range groove angle dimensions a w wb d x s e ° mm mm mm mm mm mm spz up to 80 34 9,7 8,5 11 2 12 8 over 80 38 Click on the images below to enlarge. Calculate the required speed ratio between. Web pulley dimensional and identification guide. Spz, spa, spb and spc. Belts · fender flares · parts & accessories V and flat belt design and engineering data. Measuring a v belt or flat pulley is easy. Web pulley dimensional and identification guide. D₁ × n₁ = d₂ × n₂. V and flat belt design and engineering data. Web what is the right size belt and pulley for your motorcycle? Web calculation and selection process. Obtain the motor’s rpm specification to understand the input speed. Measure the diameter (d₁) of the driving pulley. There will be a part number on the backside of the supercharger pulley. Calculate the required speed ratio between the motor and driven equipment based on the application’s needs. Use the applet and information below to make an educated decision when you. Web this is a list of useful definitions for use with drives pulleys, idler pulleys, and other mechanical motion parts. Diameter and rpm of each pulley. Outside diameter, or the distance across the pulley when measured between groove edges. Web learn how to measure your pulley or sheave. Each manufacturer will have different recommendations based on your project’s specifications, taking. Belt profile, or the style and sizes of the belt being integrated. Click on the images below to enlarge. The middle section of the roush supercharger pulley part number explains what size and type of pulley that has been installed. Motor and equipment speed for pulleys with different diameters are indicated in the charts below: Find the correct oem sizing. To accommodate a range of shaft sizes. Calculate the required speed ratio between the motor and driven equipment based on the application’s needs. With a comprehensive database of conveyor components, users can create custom systems and optimize costs and suppliers. Web this is a list of useful definitions for use with drives pulleys, idler pulleys, and other mechanical motion parts.. Consider belt type and width: Terre products measuring guide explains pulley specs and dimensions. Measuring a v belt or flat pulley is easy. There will be a part number on the backside of the supercharger pulley. Web the following timing belt pulley pitch diameter (p.d.) and timing belt pulley outside diameter (o.d.) charts allow the end user to quickly determine. 5/5 (1,408 reviews) In stock and ready to ship. This acts as a primer to help protect the pulleys from environmental factors. Consider belt type and width: There will be a part number on the backside of the supercharger pulley. Motor and equipment speed for pulleys with different diameters are indicated in the charts below: Obtain the motor’s rpm specification to understand the input speed. Quickly determine the size of any belt. Find the correct oem sizing below! Web what is the right size belt and pulley for your motorcycle? Each manufacturer will have different recommendations based on your project’s specifications, taking into account shaft speeds, power transmission, environment, and other concerns. Belt profile, or the style and sizes of the belt being integrated. D₁ × n₁ = d₂ × n₂. Spz, spa, spb and spc. Constructed from cast iron, each pulley is. Web pulley dimensional and identification guide.Timing Belt Pulley Diameter Charts Pfeifer Industries

Motor Pulley Size Chart

Vbelt Pulley Size Chart Pdf

Pulley Dimension Chart A Visual Reference of Charts Chart Master

Gates Idler Pulley Size Chart

Idler Pulley Size Chart

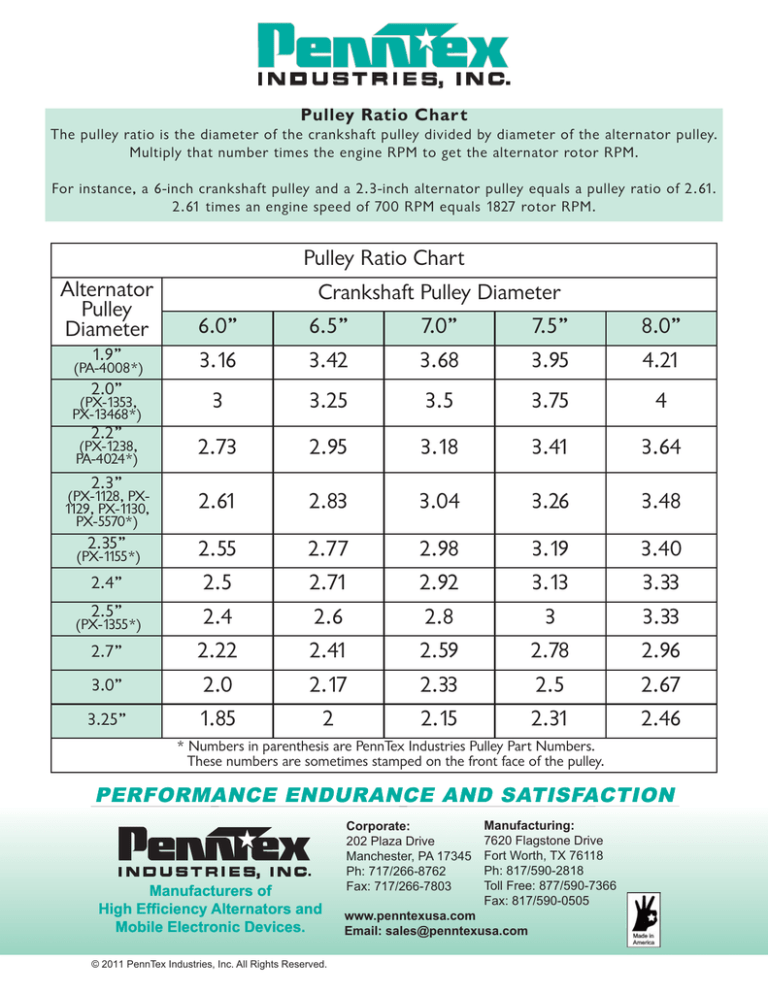

Pulley Ratio Chart PennTex Industries, Inc.

Motor Pulley Size Chart

V Belt Pulley Sheave Sizes Table Chart, 58 OFF

Vbelt Pulley Size Chart Pdf

D1 N1= D2N2 (1) Where.

Web The Following Timing Belt Pulley Pitch Diameter (P.d.) And Timing Belt Pulley Outside Diameter (O.d.) Charts Allow The End User To Quickly Determine The Dimensional Requirements For A Timing Belt Drive System.

8C 8 9 1 % 0 % % B 4 & Belt Series Pitch Diameter Range Groove Angle Dimensions A W Wb D X S E ° Mm Mm Mm Mm Mm Mm Spz Up To 80 34 9,7 8,5 11 2 12 8 Over 80 38

Terre Products Measuring Guide Explains Pulley Specs And Dimensions.

Related Post: