Tig Welding Cup Size Chart

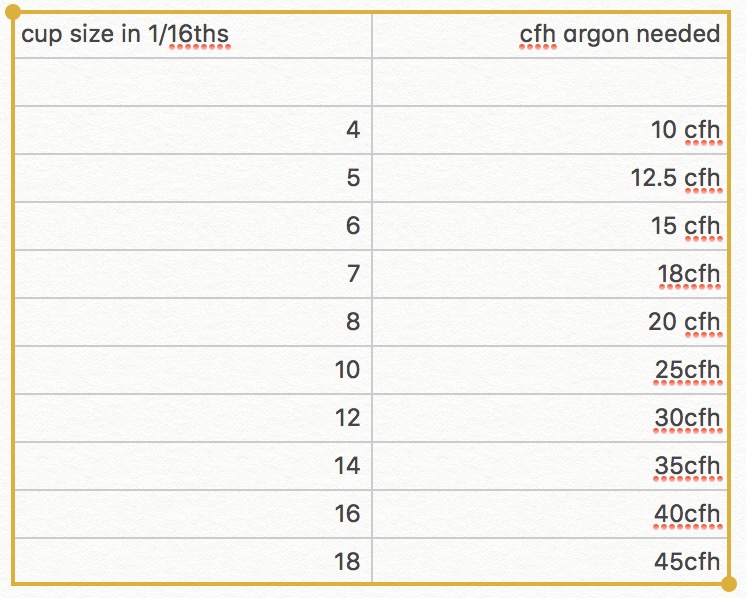

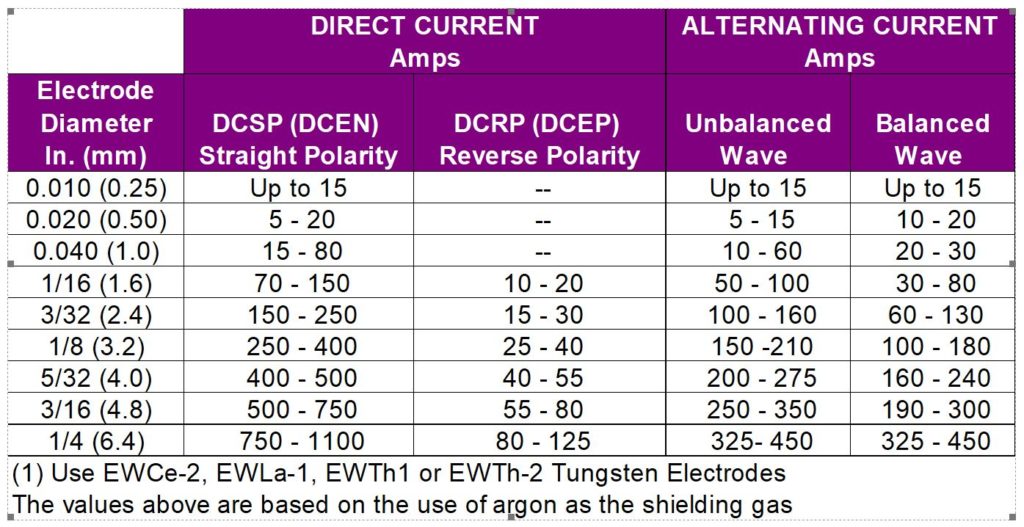

Tig Welding Cup Size Chart - In stock and ready to ship. Web the cup is a ceramic attachment that goes on the end of the tig torch that directs the argon gas onto the weld. Use ceramic cup when welding with less than 250 amps. We need a lot less flow in tig welding. Which cup works for which metal? Tig torches come in a number of sizes: For example, titanium requires an extremely large cup because it cant tolerate oxidation of the weld pool at all. The cup size impacts gas coverage, heat tolerance, and the quality of the weld. Read and follow your machine’s owner's manual and precautionary labels for complete safety, setup and installation instructions and procedures. Web empower your tig welding projects with our free online tig welding calculator. For tig welding, common choices include #4 (1/4″), #5 (5/16″), #6 (3/8″), #7 (1/16″) and #8 (1/2″). A look at each type and its uses You are using way too much gas.cut it. For example, titanium requires an extremely large cup because it cant tolerate oxidation of the weld pool at all. Web tig welder setup. Web when tig welding, there are three choices of welding current. Each of these has its applications, advantages, and disadvantages. The cups come in many different sizes. Tig torches come in a number of sizes: The following diagram and instructions show a. Each of these has its applications, advantages, and disadvantages. Web torch cup orifice diameter: The cups come in many different sizes. Web in response to a subscriber question we look at the different cup sizes for tig torches. Selecting the appropriate cup size for tig welding is essential for achieving optimal results in your welding projects. Web for beginners, it’s recommended to stick with a 3/32” diameter tungsten. 9, 17, 18 & 26. Web when tig welding, there are three choices of welding current. We need a lot less flow in tig welding. The cups come in many different sizes. Tungsten diameter and cup size. Web empower your tig welding projects with our free online tig welding calculator. Each torch uses the same types of consumables (see below) but will have their own sizes that fit. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that. Web in response to a subscriber question we look at the different cup sizes for tig torches. The size cup is largely determined by accessibility to the weld and material type. Web for beginners it’s recommended to stick with a 3/32” diameter tungsten. Tungsten diameter and cup size. If you're walking the cup and want to move fast larger cup,. If you're walking the cup and want to move fast larger cup, like slower go with smaller cup (more or less travel for each walk of the cup) A look at each type and its uses Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Choose from our selection of tig cups, including tig. Choosing the correct size depends on material thickness, joint type, and desired weld bead profile. Web when tig welding, there are three choices of welding current. We need a lot less flow in tig welding. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web tig torch selector chart. How do you set up your tig cup properly? Use ceramic cup when welding with less than 250 amps. 🛠️ cup sizes in tig welding refer. For example, titanium requires an extremely large cup because it cant tolerate oxidation of the weld pool at all. Tig cup size page 6 of this document has a handy chart for cup selection. Tungsten diameter and cup size. Wall thickness and joint design is the biggest determining factor. Web for beginners it’s recommended to stick with a 3/32” diameter tungsten. The size cup is largely determined by accessibility to the weld and material type. Web cup size (sometimes referred to as nozzle or lava cones), play an intricate part in welding pipe open. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The following diagram and instructions show a. The cups come in many different sizes. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Choosing the correct size depends on material thickness, joint type, and desired weld bead profile. Web for beginners it’s recommended to stick with a 3/32” diameter tungsten. If you're walking the cup and want to move fast larger cup, like slower go with smaller cup (more or less travel for each walk of the cup) In this article, we are going to look in detail at how you can select the. The size cup is. Web tig torch selector chart. Tig torches come in a number of sizes: Web which one works best? We need a lot less flow in tig welding. Which cup works for which metal? Tig cup size page 6 of this document has a handy chart for cup selection as it relates to amperage and gas flow: Web when tig welding, there are three choices of welding current. Web the cup is a ceramic attachment that goes on the end of the tig torch that directs the argon gas onto the weld. We need a lot less flow in tig welding. Tungsten diameter and cup size. The size and length of the cup being used is normally determined by the joint design and root opening. Web how do i choose a cup size for tig welding? Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Selecting the appropriate cup size for tig welding is essential for achieving optimal results in your welding projects. Web cup sizes are in 16th inches.some say there is relationship between cup size and diameter of tungsten, where fatter tungsten require large cup size.i don't subscribe to that. Web empower your tig welding projects with our free online tig welding calculator.Tig Cup Size Chart

Tig Cup Size Chart

How Do I Choose a Cup Size of TIG Welding [Cup Size Chart] Savant DIY

Tig Cup Size Chart

Tig Weld Amp Chart

Tig Welding Cup Size Chart Best Picture Of Chart

A Better TIG Experience Hot Rod Network

How Do I Choose a TIG Welding Cup Size? [Chart] Beginner Welding Guide

Tig Welding Settings Chart

Tig Welding Cup Size Chart Best Picture Of Chart

The Cup Size Impacts Gas Coverage, Heat Tolerance, And The Quality Of The Weld.

The Cups Come In Many Different Sizes.

A Look At Each Type And Its Uses

Adequate Gas Flow For Gmaw Typically Ranges From 35 To 50 Cubic Feet Per Hour.

Related Post:

![How Do I Choose a Cup Size of TIG Welding [Cup Size Chart] Savant DIY](https://savantdiy.com/wp-content/uploads/2023/01/TIG-welding-cup-size.webp)

![How Do I Choose a TIG Welding Cup Size? [Chart] Beginner Welding Guide](https://m.media-amazon.com/images/I/41xCIY9SFGL._SL500_.jpg)