Tig Welding Tungsten Chart

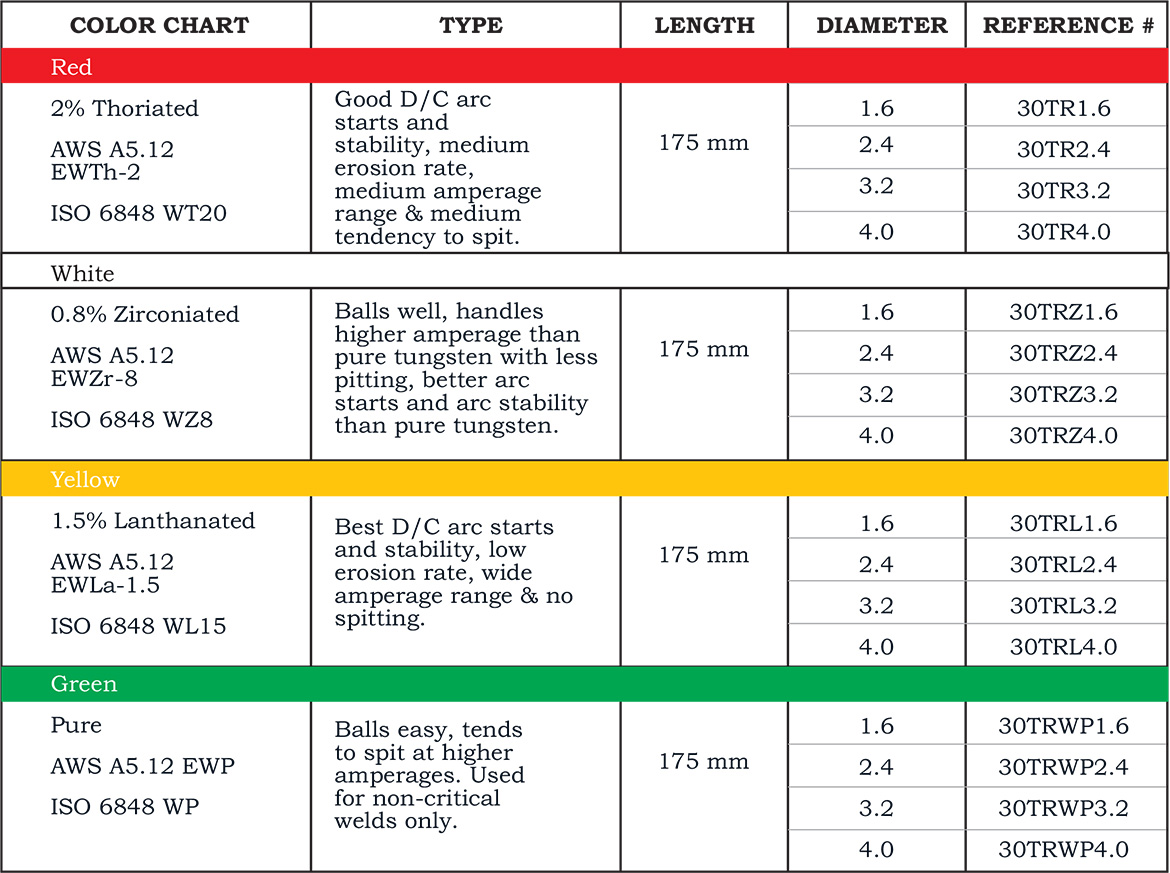

Tig Welding Tungsten Chart - Web information on specifications and usage. Web selecting the right tungsten electrode is an essential part of tig welding. Web with tungsten inert gas (tig) welding solutions, we use a tungsten electrode to complete the weld. It results in a highly polished,. Web learn the basics of tungsten inert gas welding (tig). Web mechanized tig welding encompasses a wide spectrum of applications such as precision bellows welding using.040 diameter tungsten electrode at 1.0 ampere up to high speed tube mills welding with a.250 diameter tungsten electrode using current as. Web tungsten electrodes come in various compositions, each with distinct properties that make them suitable for different applications. As we progress through this guide of tig welding electrodes, it’s important to know that there are several tig welding tungsten options that have the ability to weld a wide range of amperage with both dc and ac for aluminum. Web this article will discuss the different selection criteria for tig tungsten electrodes. Correctly matching the tungsten electrode with a weld’s requirements saves time and money. Learn from ron covell about the different tungsten electrodes available for a variety of welding applications. There are many factors that affect the choice of the right tungsten size when tig welding—the weld amperages, material thickness, and tungsten type, to name a few. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Correctly matching the tungsten electrode with a weld’s requirements saves time and money. Web what are the main types of tungstens used for welding? Development of limb independence and torch control. Tig tungsten size selection criteria. Web tungsten inert gas (tig) welding, also known as gas tungsten arc welding (gtaw), is a type of welding responsible for securing some of the world’s most important equipment and machinery. Luckily, each tungsten stick has a color code applied to one end, which identifies the material type of the tungsten. It results in a highly polished,. Gaining a better understanding of the elements of welding in order to control them as you move through the weld zone with the tig torch. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Web what are the main types of tungstens used for welding? Our chart & guide explain types. There are many factors that affect the choice of the right tungsten size when tig welding—the weld amperages, material thickness, and tungsten type, to name a few. Luckily, each tungsten stick has a color code applied to one end, which identifies the material type of the tungsten. Web learn the basics of tungsten inert gas welding (tig). It results in. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Web choosing the right tungsten for your tig weld can be a daunting task. The following are the most common types of tungsten electrodes used in tig welding: Web selecting the right tungsten electrode is an essential part of tig welding. Web. As we progress through this guide of tig welding electrodes, it’s important to know that there are several tig welding tungsten options that have the ability to weld a wide range of amperage with both dc and ac for aluminum. Web selecting the right tungsten electrode is an essential part of tig welding. Learn from ron covell about the different. Web tungsten electrodes come in various compositions, each with distinct properties that make them suitable for different applications. Browse suggested weld parameter settings for tig welding. Luckily, each tungsten stick has a color code applied to one end, which identifies the material type of the tungsten. Web tig welding allows the welder more control. Web with tungsten inert gas (tig). We break down the different tungsten colors and explain when you should use each one. Web when it comes to tig welding, the most commonly asked question is “what tungsten do i use?” this tungsten selection guide will help you select the correct tungsten for your tig application. Web mechanized tig welding encompasses a wide spectrum of applications such as. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Browse suggested weld parameter settings for tig welding. Web when it comes to tig welding, the most commonly asked question is “what tungsten do i use?” this tungsten selection guide will help you select the correct tungsten for your tig application. Web. Our chart & guide explain types (pure, ceriated, etc.), colors, & best uses for flawless tig welds on steel, aluminum, & more! It results in a highly polished,. Web the tungsten electrodes required for tig welding come in various sizes and types, each working with varying amperage. The current polarity, power source, thickness of the material, and metal type play. As we progress through this guide of tig welding electrodes, it’s important to know that there are several tig welding tungsten options that have the ability to weld a wide range of amperage with both dc and ac for aluminum. Web mechanized tig welding encompasses a wide spectrum of applications such as precision bellows welding using.040 diameter tungsten electrode at. Selecting the right tungsten electrode is an essential part of tig welding. Web tig welding allows the welder more control. There are many factors that affect the choice of the right tungsten size when tig welding—the weld amperages, material thickness, and tungsten type, to name a few. Web selecting the right tungsten electrode is an essential part of tig welding.. Web what are the main types of tungstens used for welding? What metal are you welding? Learn from ron covell about the different tungsten electrodes available for a variety of welding applications. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Web with tungsten inert gas (tig) welding solutions, we use a tungsten electrode to complete the weld. Here is a great reference guide to help you determine which electrode is right for your next job. Browse suggested weld parameter settings for tig welding. Web tungsten electrodes come in various compositions, each with distinct properties that make them suitable for different applications. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Correctly matching the tungsten electrode with a weld’s requirements saves time and money. Selecting the right tungsten electrode is an essential part of tig welding. There are many factors that affect the choice of the right tungsten size when tig welding—the weld amperages, material thickness, and tungsten type, to name a few. Web not sure which tungsten electrode to use? Web the tungsten electrodes required for tig welding come in various sizes and types, each working with varying amperage. Web when it comes to tig welding, the most commonly asked question is “what tungsten do i use?” this tungsten selection guide will help you select the correct tungsten for your tig application. Tig tungsten size selection criteria.Tungsten Chart For Tig Welding

TIG Tungsten Electrodes Explained (with Color Chart)

TIG Tungsten Electrodes Explained (with Color Chart)

Tig Welding Electrode Color Chart

The different types of electrodes used in orbital TIG welding

Tig Tungsten Color Chart

TIG Tungsten Electrode Types Jasic Blog

Tungsten Chart For Tig Welding

Tig Tungsten Chart Labb by AG

Tig Welding Tungsten Chart

Web Tungsten Inert Gas (Tig) Welding, Also Known As Gas Tungsten Arc Welding (Gtaw), Is A Type Of Welding Responsible For Securing Some Of The World’s Most Important Equipment And Machinery.

Development Of Limb Independence And Torch Control.

Web Tig Welding Allows The Welder More Control.

Web Learn The Basics Of Tungsten Inert Gas Welding (Tig).

Related Post: