Welding Wire Size Chart

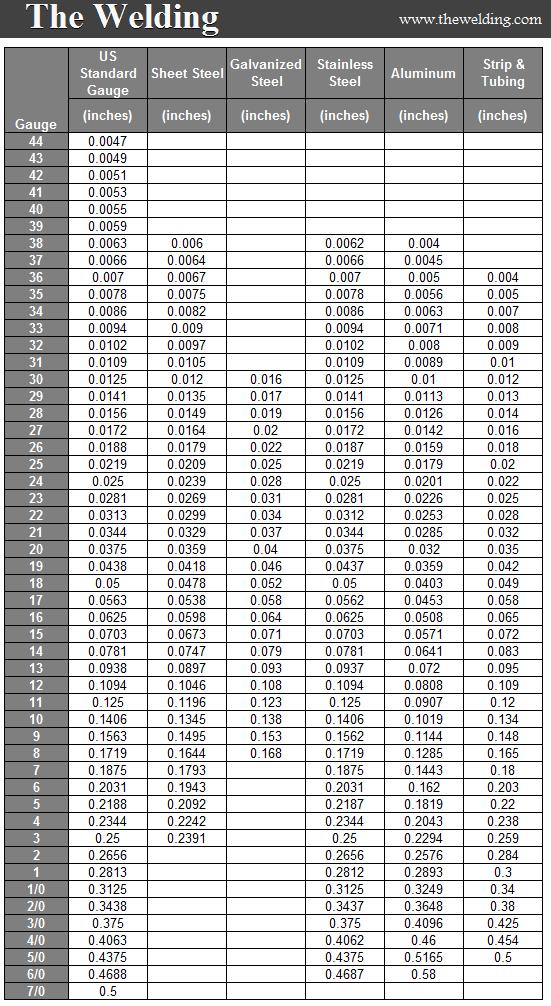

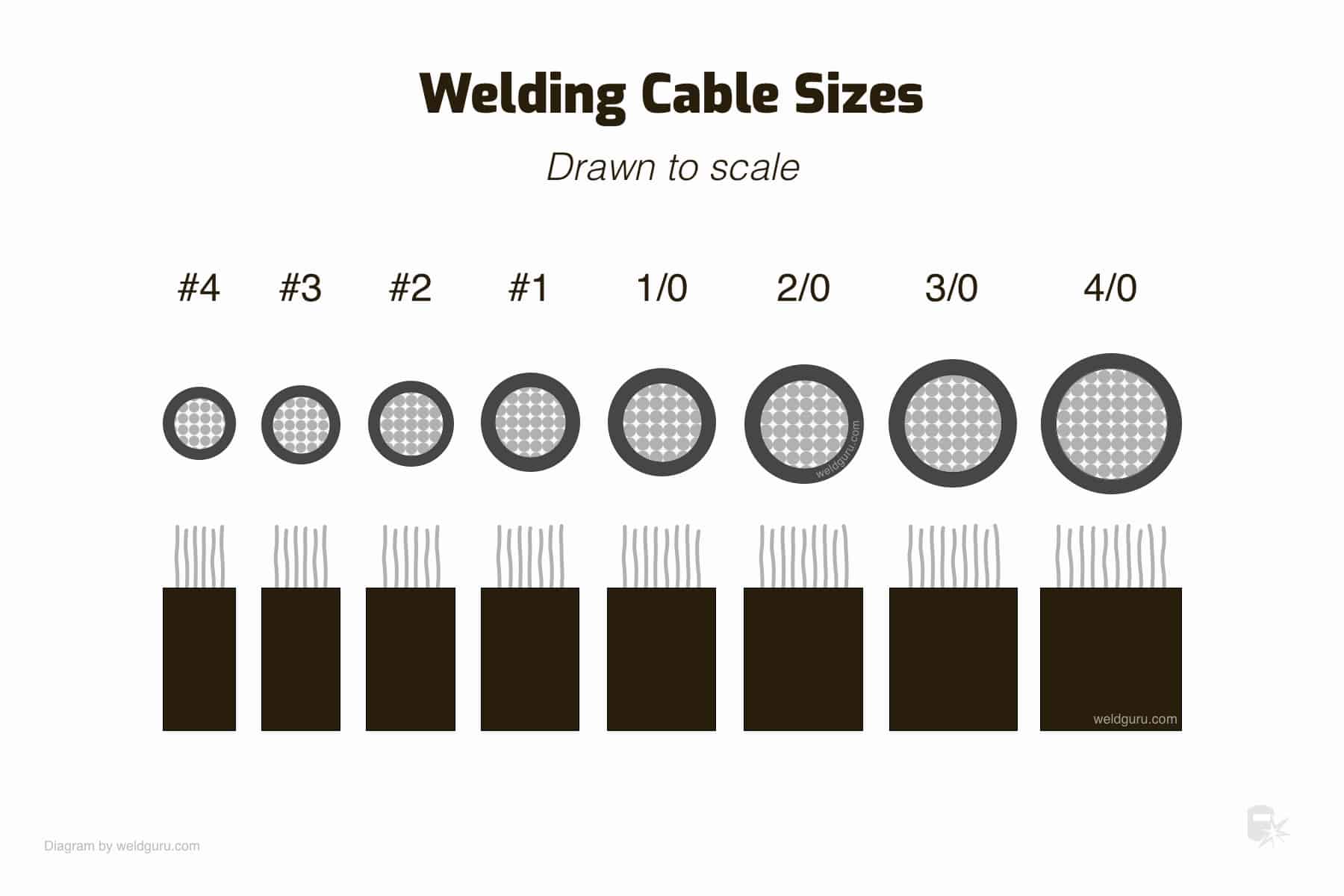

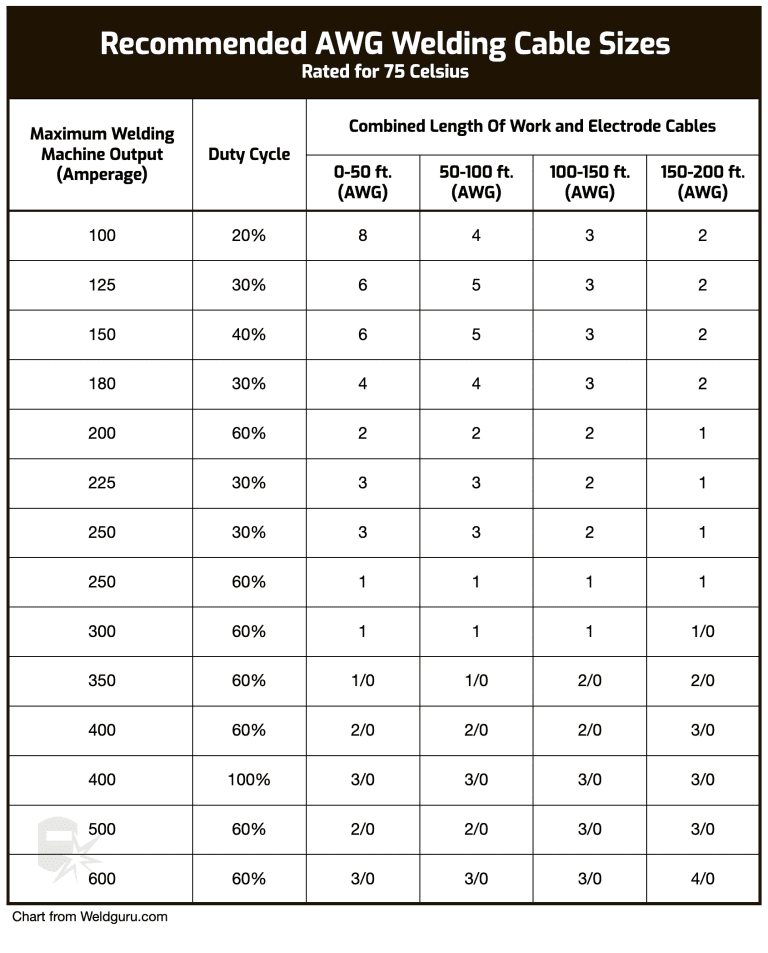

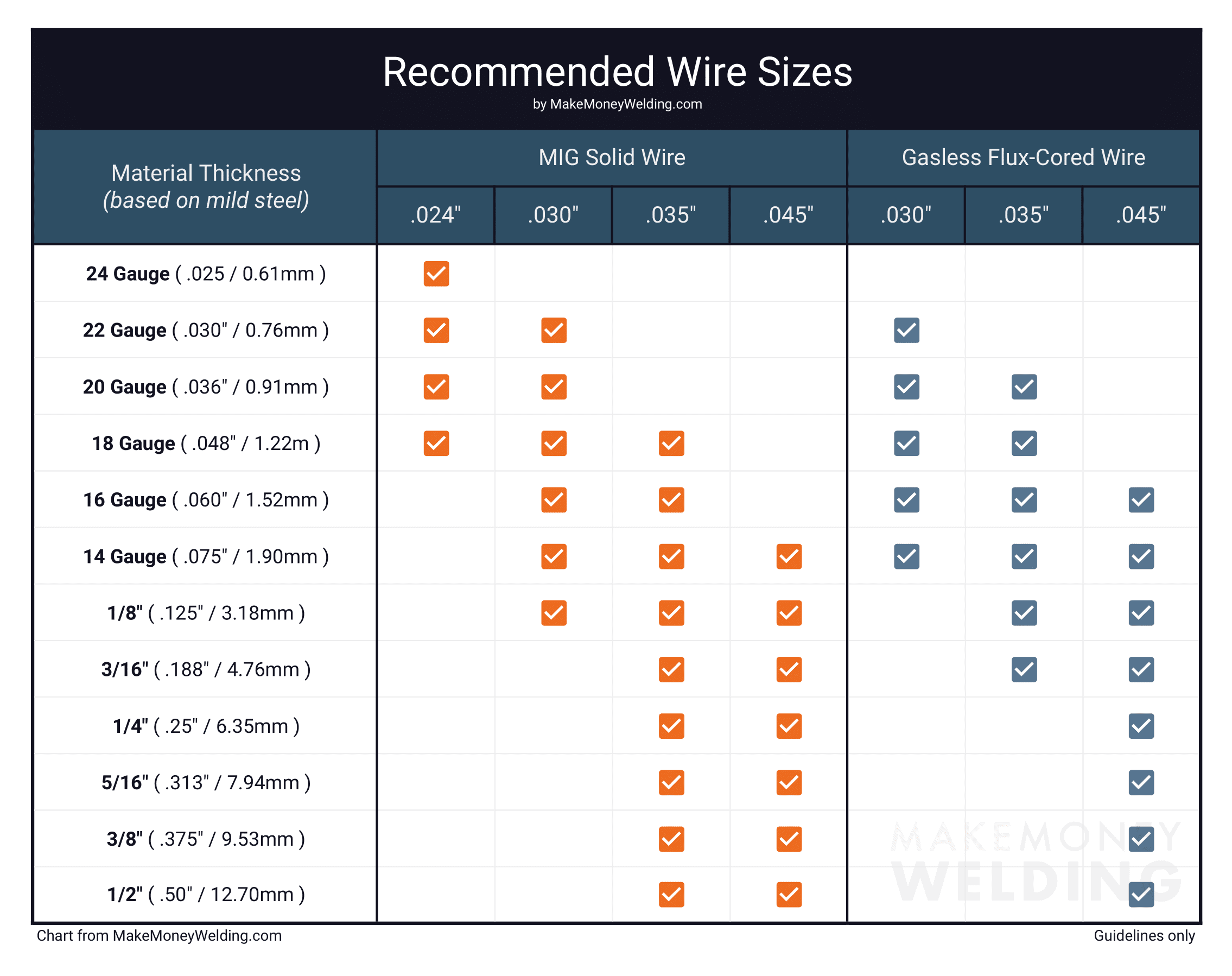

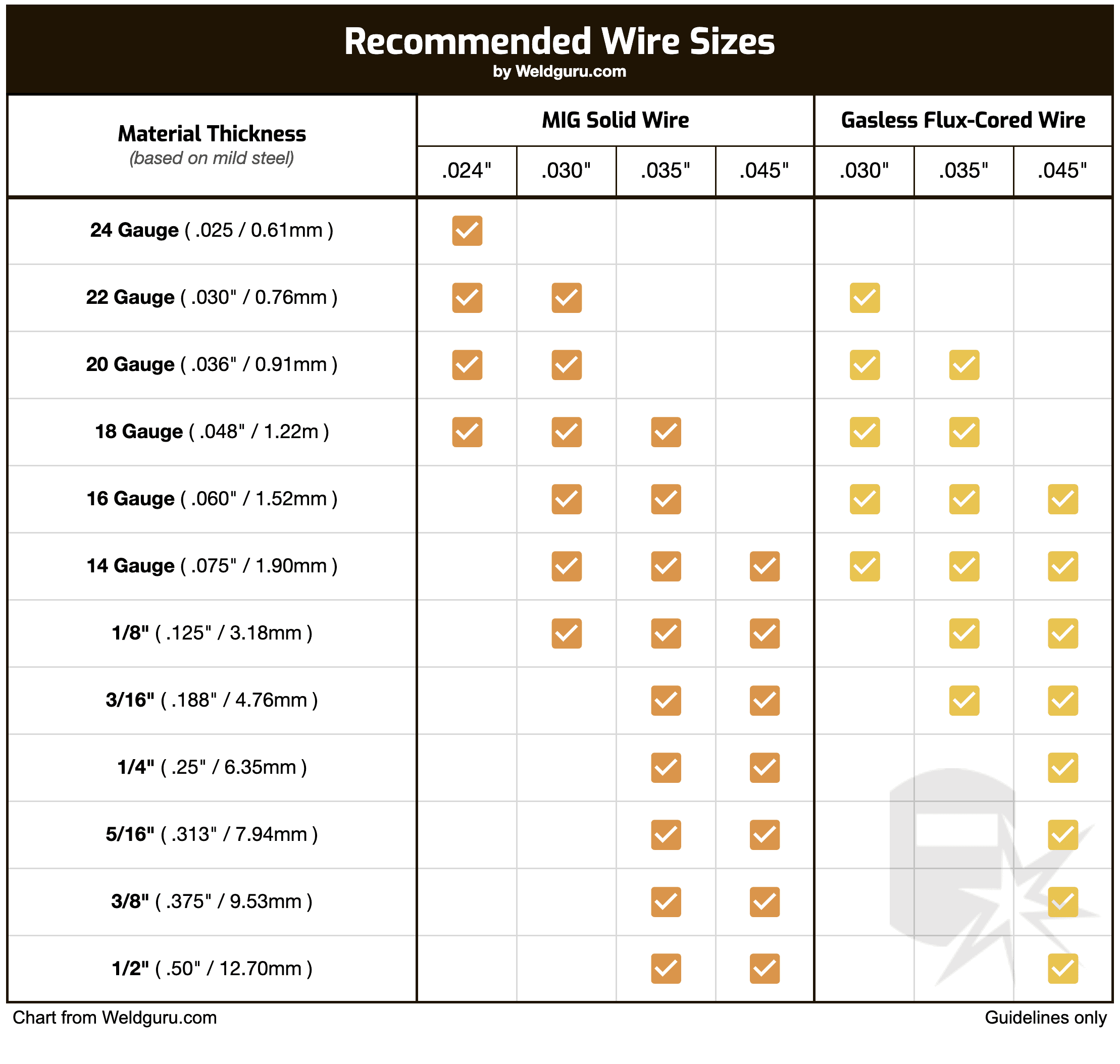

Welding Wire Size Chart - Web selecting the appropriate mig wire size is crucial for successful welding. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. Web how to choose the right mig wire for a good weld strength. In making a mig wire. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Web this chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. The electrode cable attaches to either an electrode. Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. In making a mig wire. Web how to choose the right mig wire for a good weld strength. Web this chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. The electrode cable attaches to either an electrode. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. The wire acts as the filler material that melts and joins metal pieces together during. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the. Web selecting the appropriate mig wire size is crucial for successful welding. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Web how to choose the right mig wire for a good weld strength. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. In making a mig wire. Web selecting the appropriate mig wire size is crucial for successful welding. The wire acts as the filler material that melts and joins metal pieces together during. Web the most common sizes. Web how to choose the right mig wire for a good weld strength. Web selecting the appropriate mig wire size is crucial for successful welding. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using. The wire acts as the filler material. The wire acts as the filler material that melts and joins metal pieces together during. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Web how to choose the right mig wire for a good weld strength. Web the most common sizes. Web how to choose the right mig wire for a good weld strength. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. The electrode cable attaches to either an electrode. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Choosing the right type of mig wire is critical for the look and strength of the welds you create. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. The wire acts as the filler material that melts and joins metal pieces together during. Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. In. Choosing the right type of mig wire is critical for the look and strength of the welds you create. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using. Web this chart is a helpful guide for choosing the correct wire size. Web how to choose the right mig wire for a good weld strength. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. The wire acts as the filler material that melts and joins metal pieces together during. Web selecting the appropriate mig wire size is crucial. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Choosing the right type of mig wire is critical for the look and strength of the welds you create. The electrode cable attaches to either an electrode. Web direct wire’s welding cable ampacity chart helps you pick the right welding cable gauge & length. Web in this article, we’ll navigate the key points, from deciphering cable and lead size charts to pinpointing the exact cable size that fits your specific needs using. Web this chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. In making a mig wire. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. Web selecting the appropriate mig wire size is crucial for successful welding.Welding Wire Gauge Chart

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Welding Wire Size Chart Mechanic's Corner Pinterest Welding wire

Welding Cable Size Guide Charts & Tips for the Right Choice

Welding Cable Size What's Best? (with Chart)

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks

MIG Welding Wire Essentials A Guide to Types & Uses

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Welding Cable Size Chart

Welders Discount Warehouse, , STAINLESS STEEL 309 MIG WIRE

Web The Most Common Sizes For Welding On Sheet Metal Are 0.35 And 0.45.

Web How To Choose The Right Mig Wire For A Good Weld Strength.

The Wire Acts As The Filler Material That Melts And Joins Metal Pieces Together During.

Related Post: